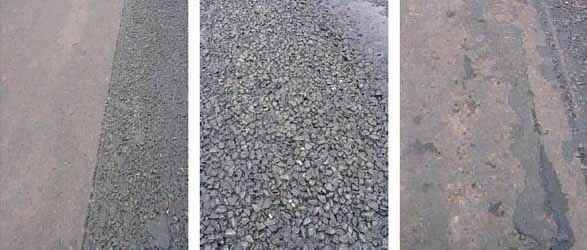

| • See examples of waste recovery below. |

| The hydrostatic drive

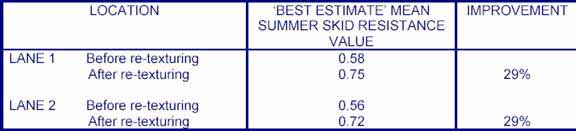

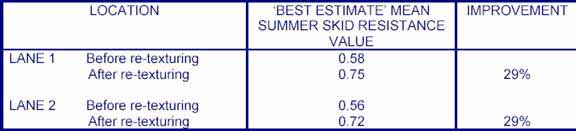

system enables variable-operating speeds of 0-10 KPH thereby ensuring full control at all times even at long gradients of 25%. Extensive testing has been carried out to prove this process and copies of the results achieved are available on request. An example is shown below courtesy of Southampton City Council (A3074 - 1997) The wet skid resistance data obtained can be summarized as follows: Fig 1 |

| The Grip Testing method

is not yet entirely accepted in some quarters and that the industry still relies on surface texture being measured by SCRIM and sand patch or laser correlated equivalent. Most of the test results we have are obtained are by portable skid tester and sand patch |

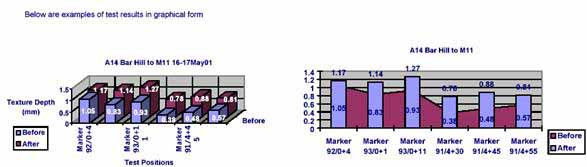

| The especial benefits

of these Captive Hydrology machines, particularly when employed for re-texturing are as follows: • Speed of operation; texturing rates of 15,000 M2 per day have been achieved • One pass – completed process • Virtually all-weather process giving a distinct advantage over alternative, weather susceptible processes • Surface virtually dry and immediately Trafficable • Life of the pavement extended by 3-5 years • Minimal disruption due to mobile traffic management • Highly environmentally friendly; 100% captive and arisings are drawn into an 11m3 tank and can be transferred into a vacuum tanker for disposal at a controlled site where the water used is recycled. (Environmental Protection Act fully complied with) • Economic – at least 40% cheaper than traditional surface dressing and 90% cheaper than Hot Rolled Asphalt! • Quality Assured – ISO 14000 accreditation is now being pursued by the authors company. |

|

|

|

|

| Examples of the effectiveness of the vacuum waste recovery system |